MirrorCoat

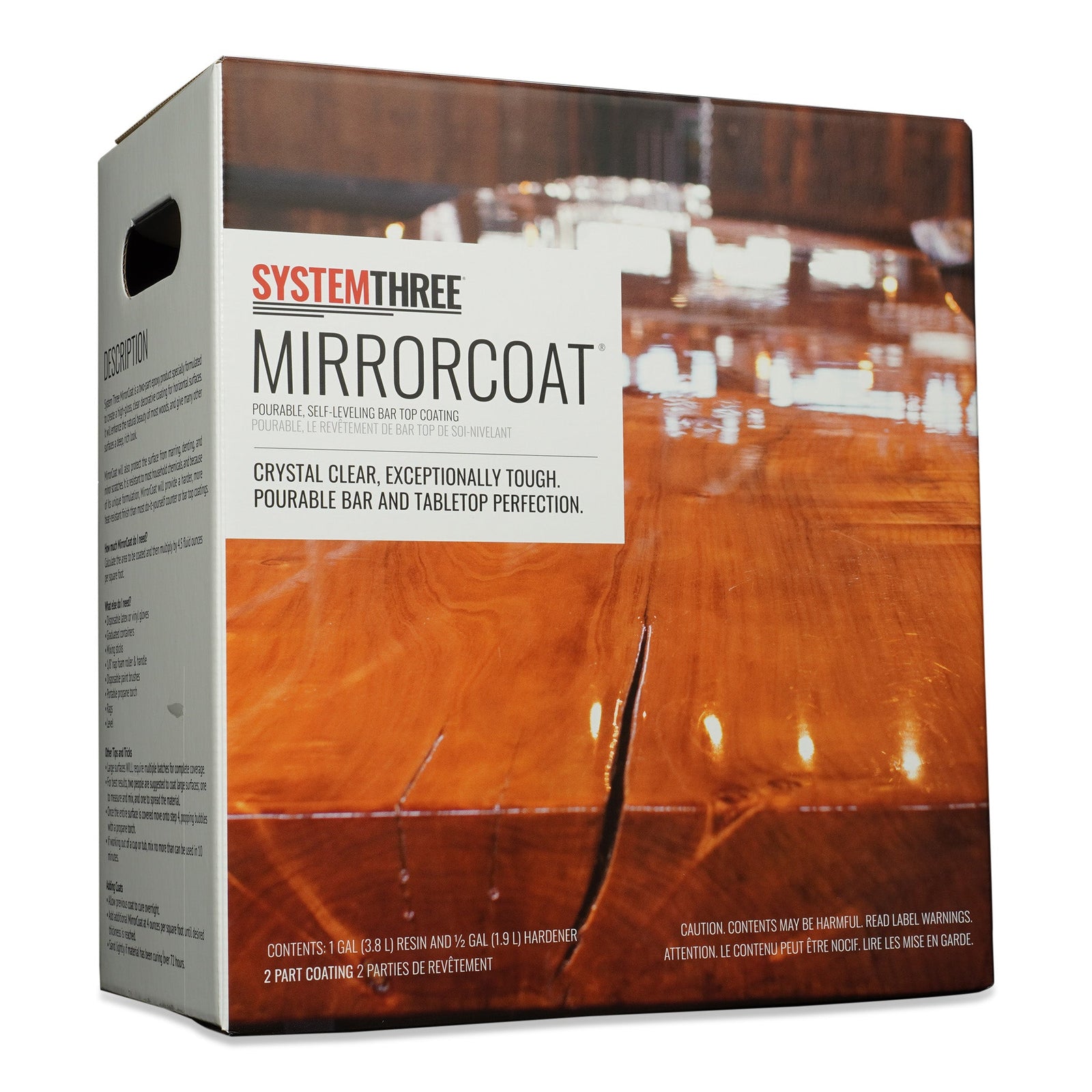

Description

MirrorCoat

Features

Properties

Mix Ratio

Minimum Application Temperature

Full Cure

Pourable Perfection

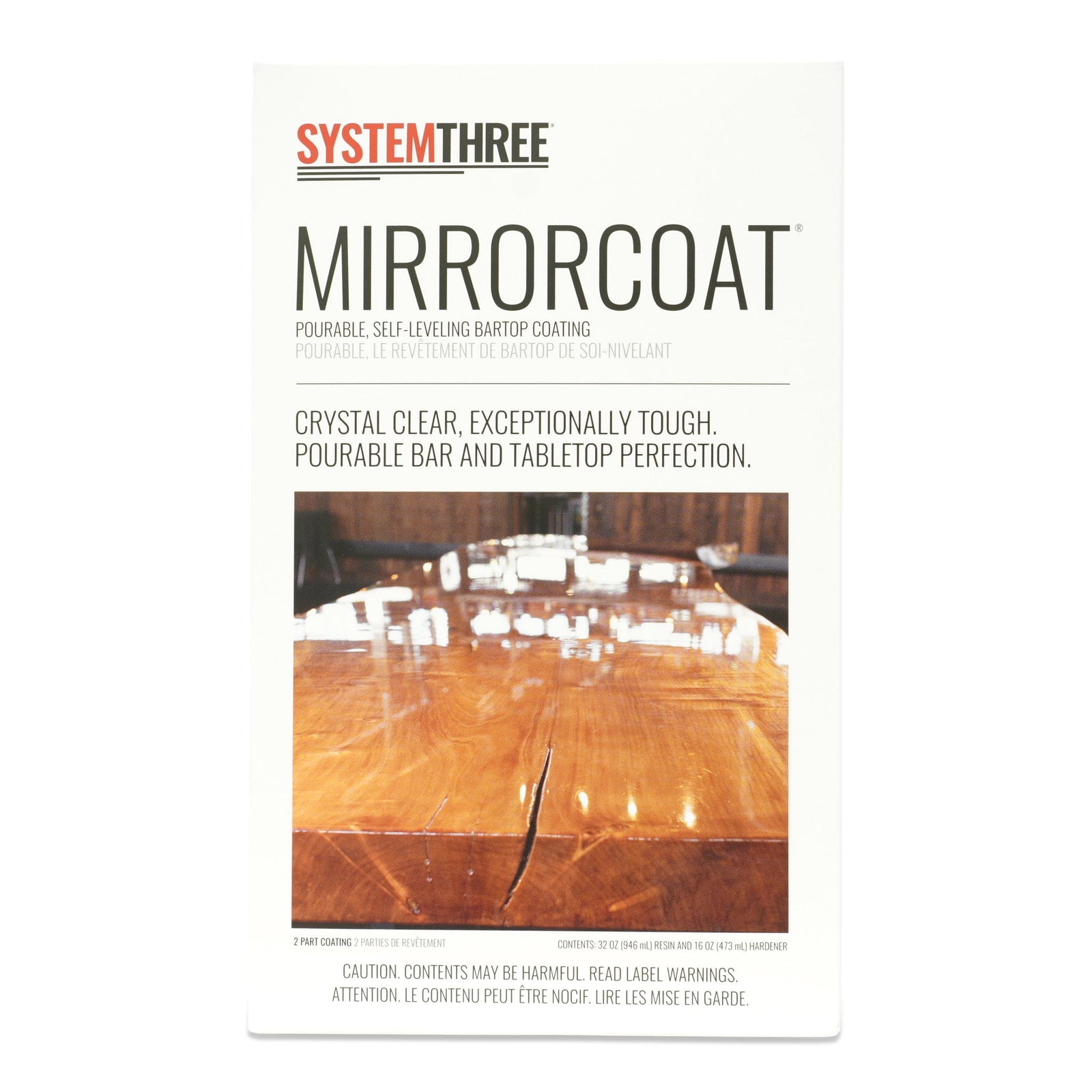

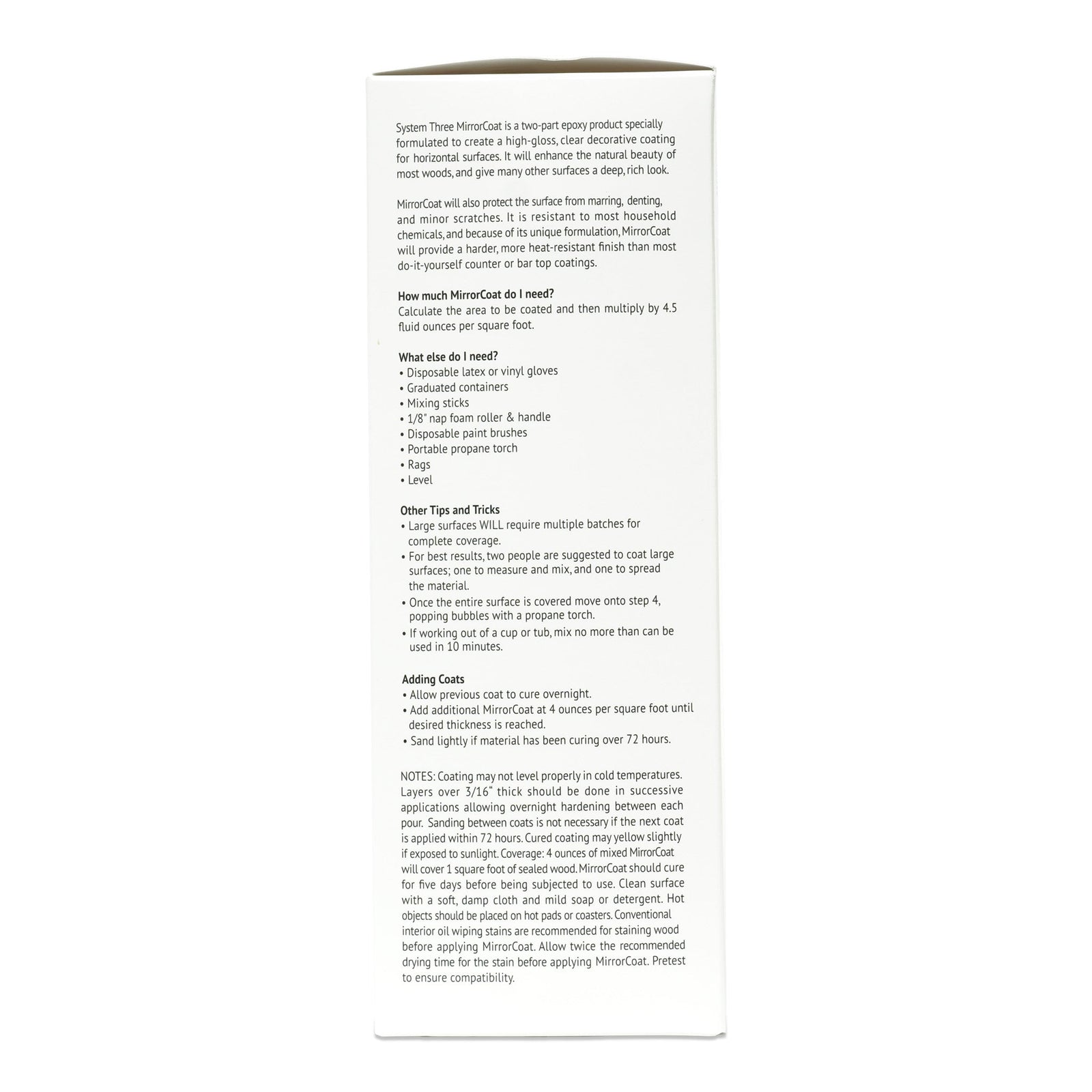

From neighborhood watering hole to high-end steakhouses, MirrorCoat can be seen in bars and restaurants around the world.

Perfect every angle and protect them in the process.

With MirrorCoat on your next live edge slab project, you are sure to get the professional result you expect from the most trusted brand of epoxy in the woodworking industry.

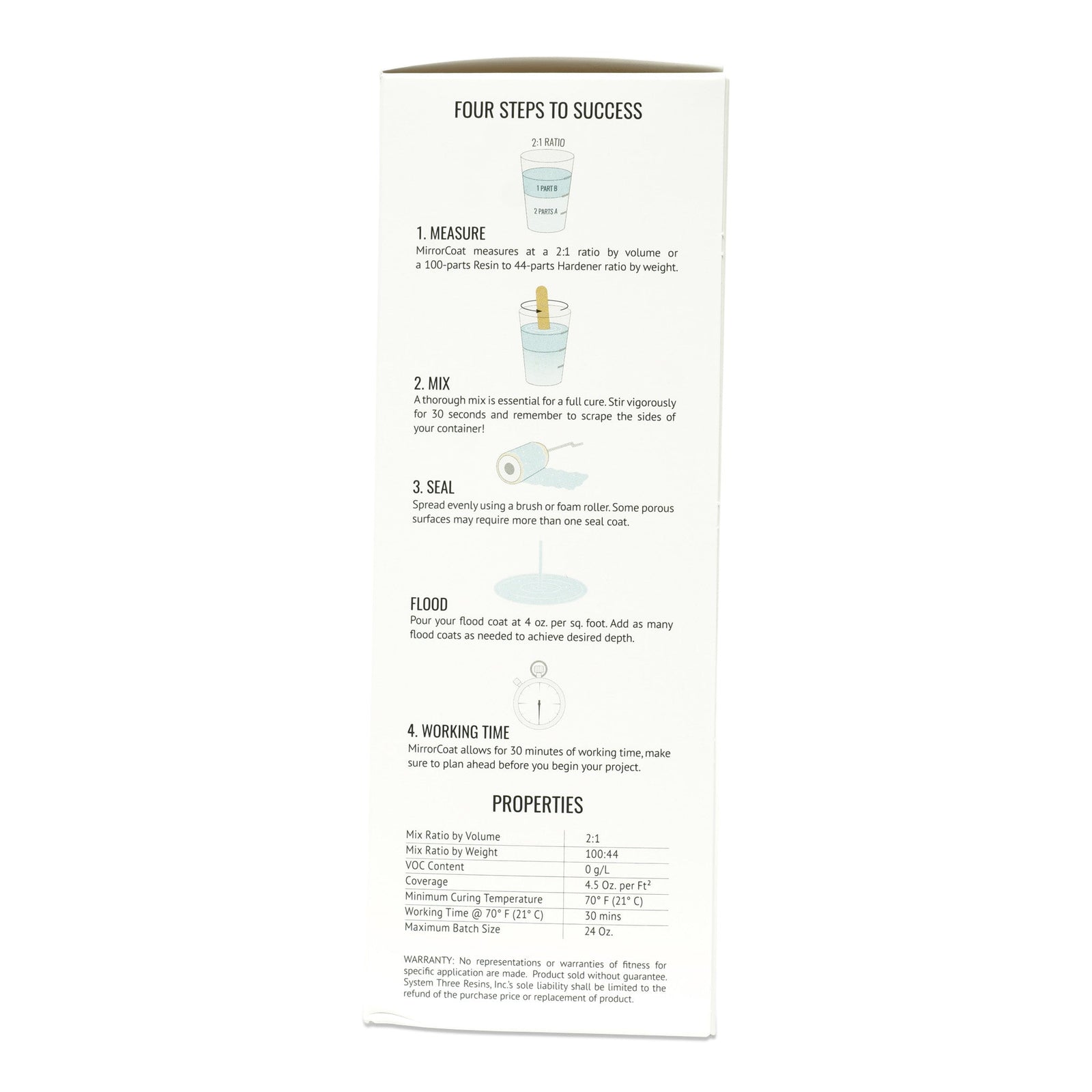

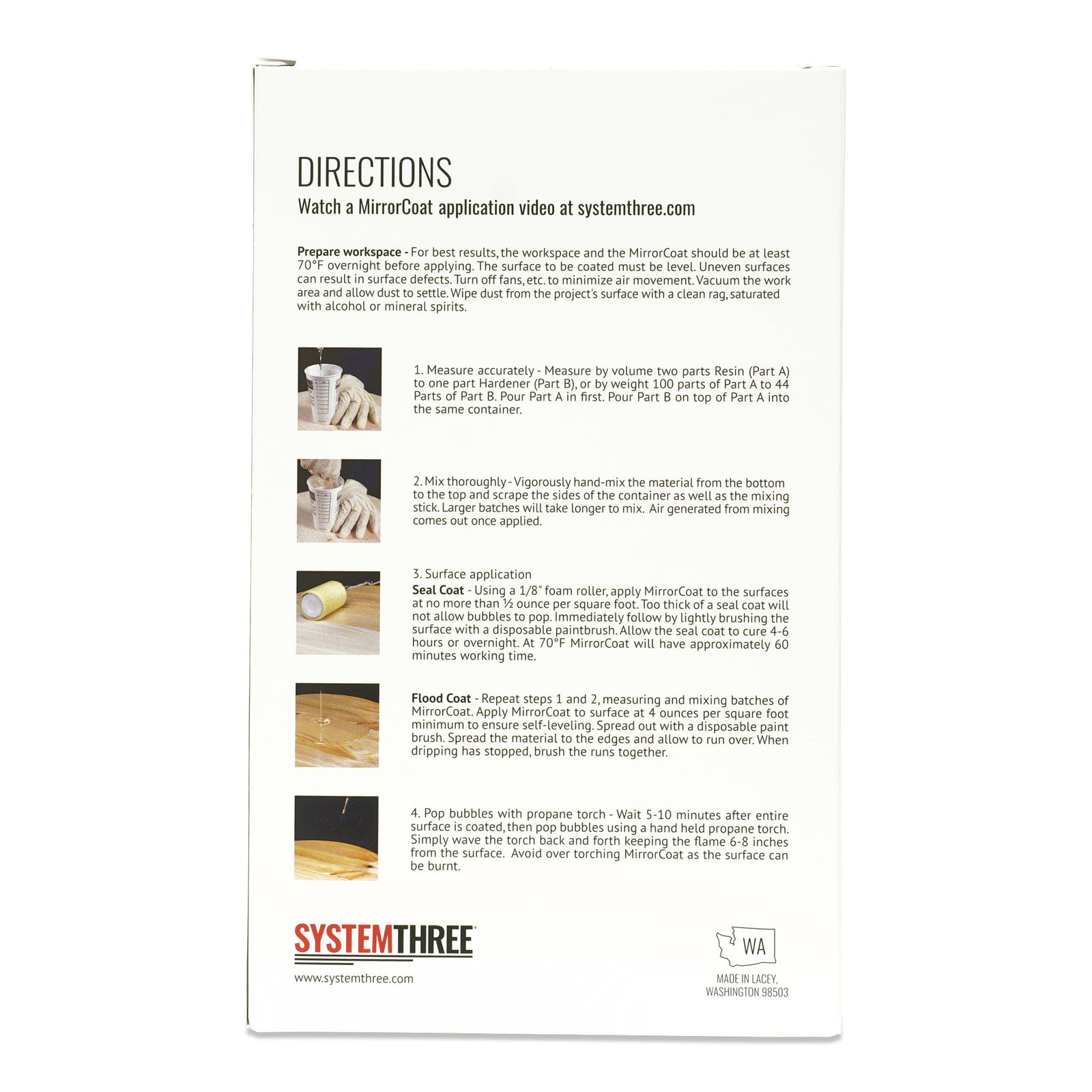

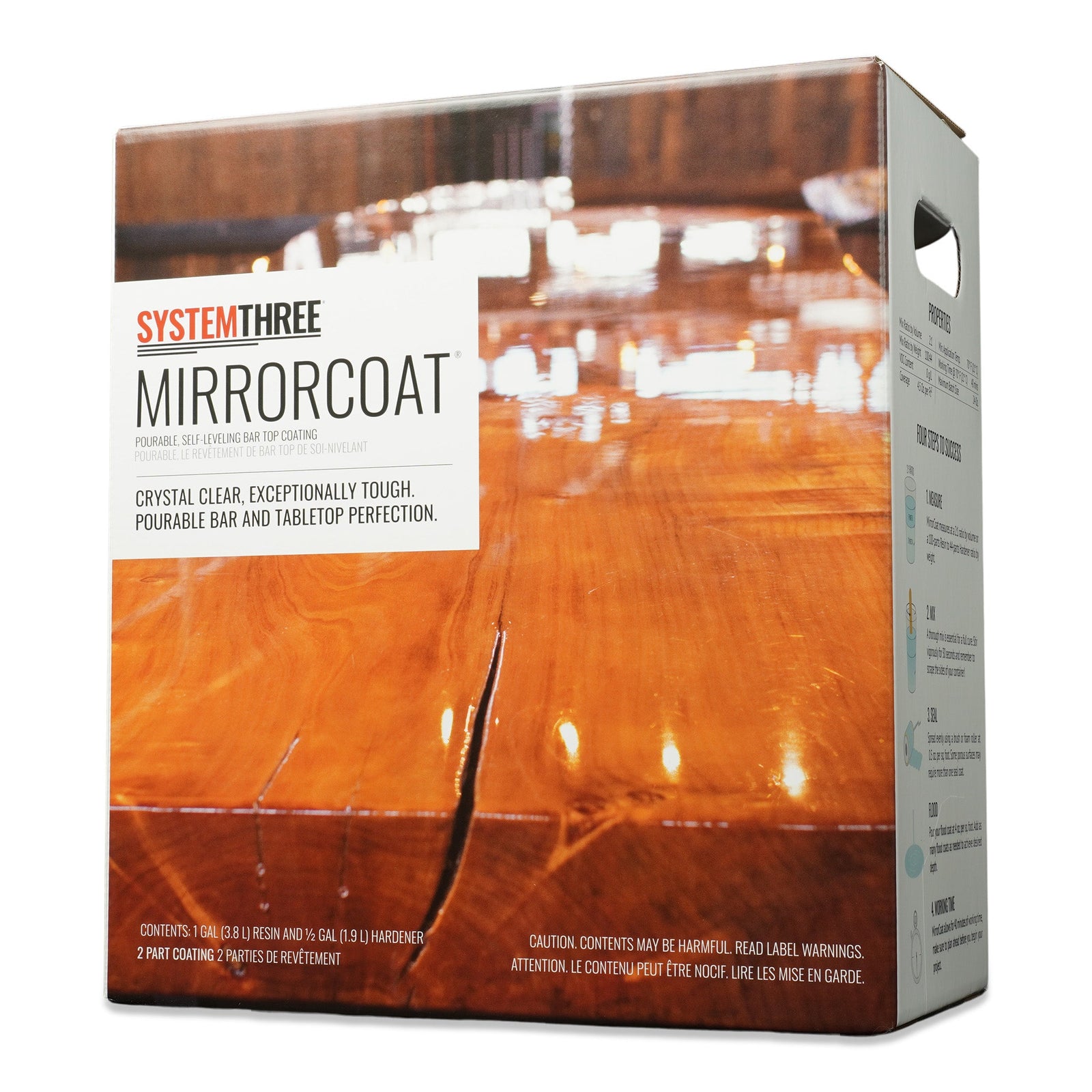

MirrorCoat Application Steps

Measure by volume two parts Resin (Part A) to one part Hardener (Part B), or by weight 100 parts of Part A to 44 Parts of Part B. Pour Part A in first. Pour Part B on top of Part A into the same container.

Vigorously hand-mix the material from the bottom to the top and scrape the sides of the container as well as the mixing stick. Larger batches will take longer to mix. Air generated from mixing comes out once applied.

Using a 1/8" foam roller, apply MirrorCoat to the surfaces at no more than ½ ounce per square foot. Too thick of a seal coat will not allow bubbles to pop. Immediately follow by lightly brushing the surface with a disposable paintbrush. Allow the seal coat to cure 4-6 hours or overnight. At 70°F MirrorCoat will have approximately 40 minutes working time.

Repeat Steps 1 and 2, measuring and mixing batches of MirrorCoat. Apply MirrorCoat to surface at 4 ounces per square foot minimum to ensure self-leveling. Spread out with a disposable paint brush. Spread the material to the edges and allow to run over. When dripping has stopped, brush the runs together.

Wait 5-10 minutes after entire surface is coated, then pop bubbles using a hand held propane torch. Simply wave the torch back and forth keeping the flame 6-8 inches from the surface. Avoid over torching MirrorCoat as the surface can be burnt.

MirrorCoat in Action

MirrorCoat FAQ

-

-

What is MirrorCoat's heat resistance / temperature tolerance?

-